Single drum dryers are widely used in building materials, metallurgy, environmental protection, mining, petrochemical, casting, chemical and other industries. They are suitable for drying high-humidity and high-viscosity materials such as coal slime, lepidolite, clay, distiller's grains, kaolin, sawdust, bentonite, fluorite powder, etc.@

E-mail :

info@tongdingmachinery.comCapacity : 31-181 t/d

Heat Source :Suitable for biomass, natural gas, diesel, coal, etc.

Our company offers tailored solutions to meet the unique requirements of each raw material, including production capacity, application specifications, cost control, degree of automation, and optimization of the drying process technology, as well as the working conditions at the site.

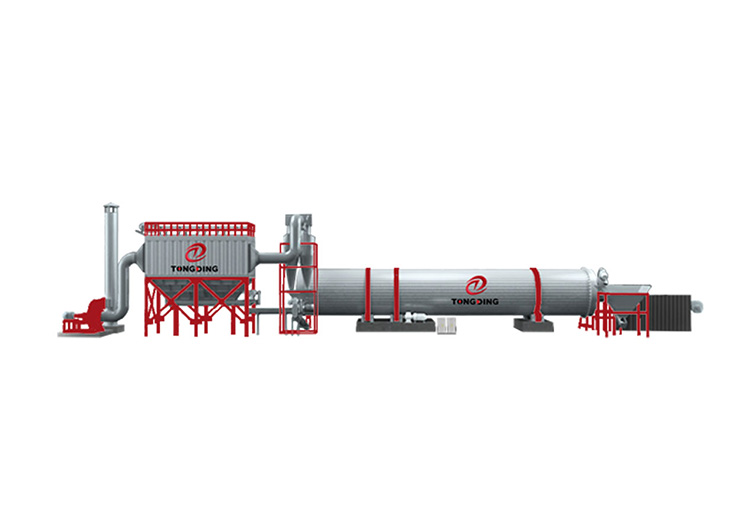

Our recommended product, the Single Drum Dryer, has a larger unit capacity and is highly efficient, saving energy while occupying less space. This dryer can save more than 50% energy compared to ordinary dryers, making it a cost-effective solution for maximizing energy savings and reducing drying costs.

Material flow : The material with a moisture content of 75-85% is fed into a specialized dehydration machine. The screw conveyor removes water to about 65% before it is sent downstream for drying in the mixing drum dryer. The flights within the drum pick up the material, carrying it over and showering it through the air stream as the drum rotates. This promotes maximum heat transfer efficiency between the material and the drying air, resulting in rapid water vaporization and material drying under the hot air's rapid flow.

To prevent buildup near the wet material discharge, the rotary drum dryer allows the material to dry before it reaches the next set of flights. Furthermore, a drum cleaning device is installed within the drum to prevent any sticking issues with the material.

The hot air furnace increases the air pressure through an air blower, heating the air to 600-850℃. Once the temperature is reached, the hot air enters the dryer and dries the wet material, and evaporates the water through the inducing draft fan. Through a three-layer heat transfer process, the air temperature reduces to 55-65℃ before being discharged from the dryer. Finally, the dust and moisture are purified through the cyclone dust collector and wet dust collector.

Airflow : The air is pressurized by the air blower and enters the hot air furnace for heating. When the temperature reaches 600-850℃, the hot air is introduced into the dryer to dry the wet material and evaporate the water with the help of the inducing draft fan. Through a three-layer heat transfer process, the air temperature gradually reduces to 55-65℃ before being discharged from the dryer. The dust and moisture are then purified through the cyclone dust collector and wet dust collector.

Single drum dryers are widely used in building materials, metallurgy, environmental protection, mining, petrochemical, casting, chemical and other industries. They are suitable for drying high-humidity and high-viscosity materials such as coal slime, lepidolite, clay, distiller's grains, kaolin, sawdust, bentonite, fluorite powder, etc.

Clay

Coal Mud

Gypsum

Lithium mica

Mineral sludge

Kaolin

distiller's-dried-grains-(DDG)

swell-soil

| Model | Φ2.4x24m | Φ3.0x30m | Φ3.2x32m | Φ3.6x36m | Φ4.0x40m |

| Inner diameter (mm) | 2400 | 3000 | 3200 | 3600 | 4000 |

| Length (mm) | 24000 | 30000 | 32000 | 36000 | 40000 |

| Power (kW) | 37 | 75 | 132 | 280 | 315 |

| Inclination (°) | 0-5 | ||||

| Shaft rotational speed (r/min) | 2-4 | 1-3 | |||

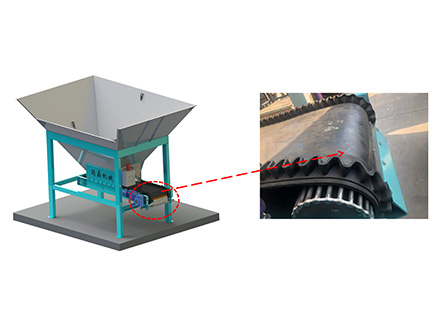

Store wet materials.

Special design of silo, enable no remaining material at four corners. Equip with belt feeder.

Convey materials.

High temperature resistance. Moisture proofing. Rubbing resistance.

Programmable logic controller, Ignition transformer, Servo motor, Wind pressure switch, ow pressure switch and magnetic valve.

Provide heat to dryer. Internal by refractory brick laying.

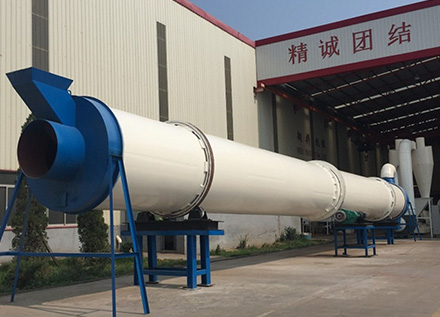

Dry wet materials comprehensively.

High wear resistance. Widen running belt to increase the stability abd extent service life. Running belt excursion by applying our patented technology. Water tank under the frame, reducing the heat and resist skid.

Collect dust more effectively.

Separation of impurities, such as the soil in the finished sand.

Convey materials.

High temperature resistance. Moisture proofing. Rubbing resistance.

Screen material to different sizes.

Install special motor(export-oriented motor) from Xinxiang motor factory.

Effectively screen out qualified materials.

Don't Hesitate Contact Us For Better Help & Services

E-mail :

info@tongdingmachinery.comTel / Whatsapp / Wechat :

+86 13673306161Fax :

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo